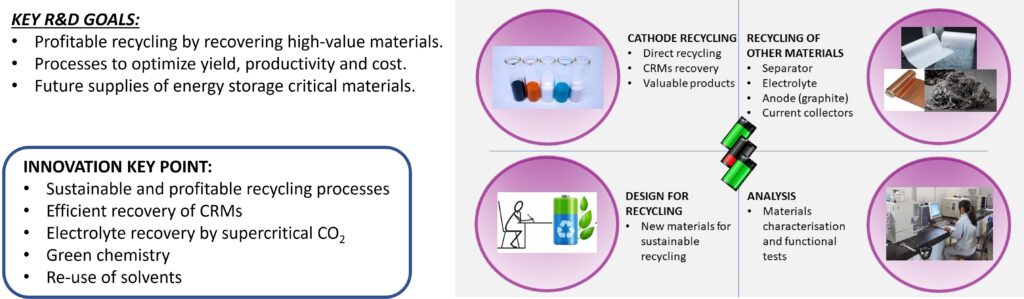

R2BATT aims to develop processes and technologies for the recycling of electrochemically active materials making up Li-ion cells through:

- the development of protocols for the extraction and separation of critical elements and compounds, based on ionic liquids or deep eutectic solvents

- the development of protocols for the extraction of polymeric components, solvents, and lithium salts with processes at ambient pressure or in supercritical conditions

- the development of measurement protocols for product quantification

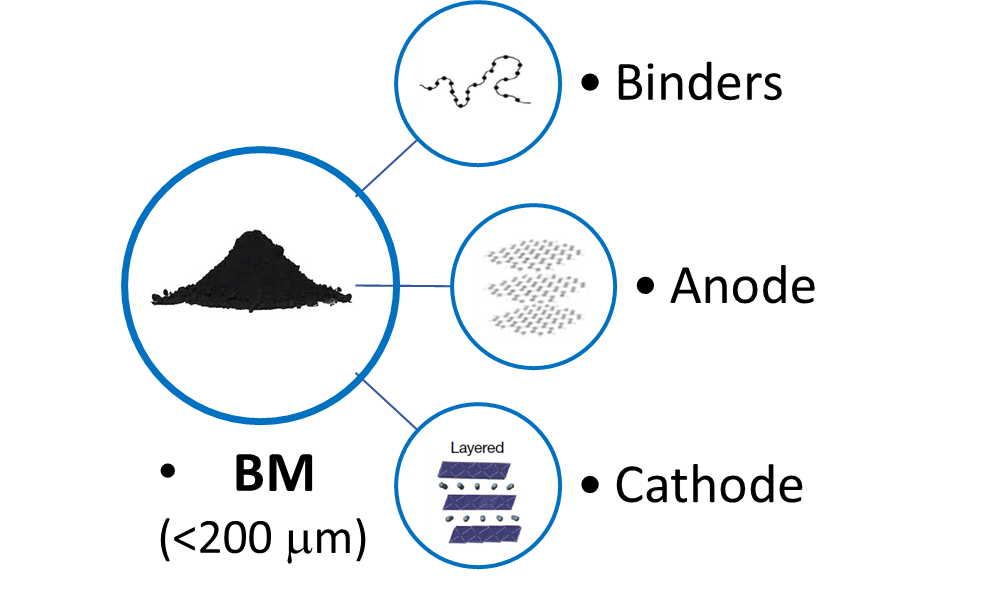

- the development of sustainable chemical treatments for the treatment of black mass

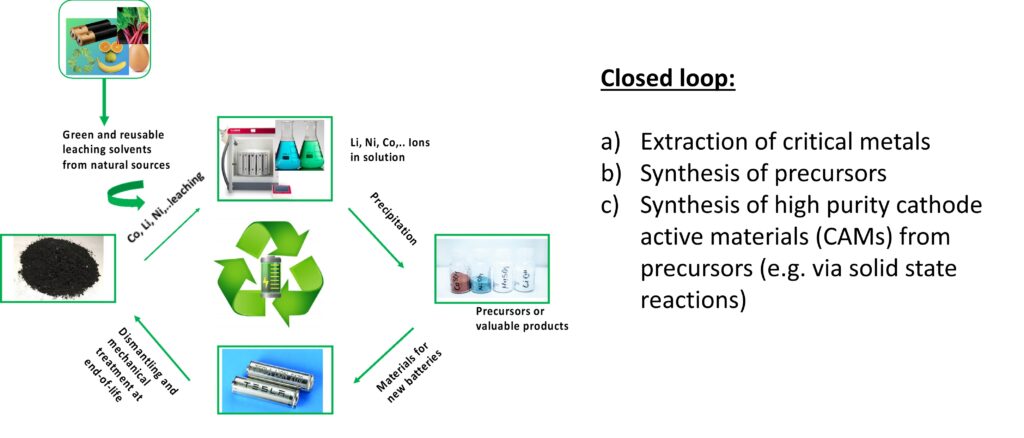

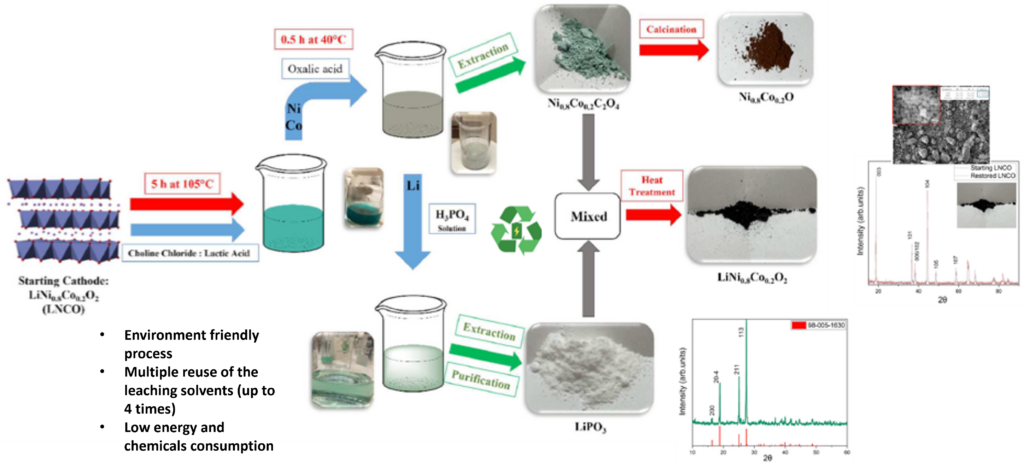

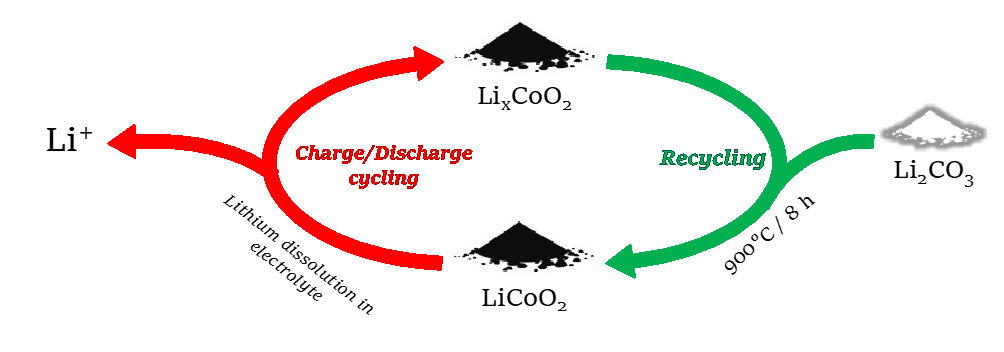

Therefore, one of the focuses is Cathode Recycling, which can be obtained by following two paths:

- recycling 1° route = Solvo-Metallurgy

- recycling 2° route = Direct Recycling

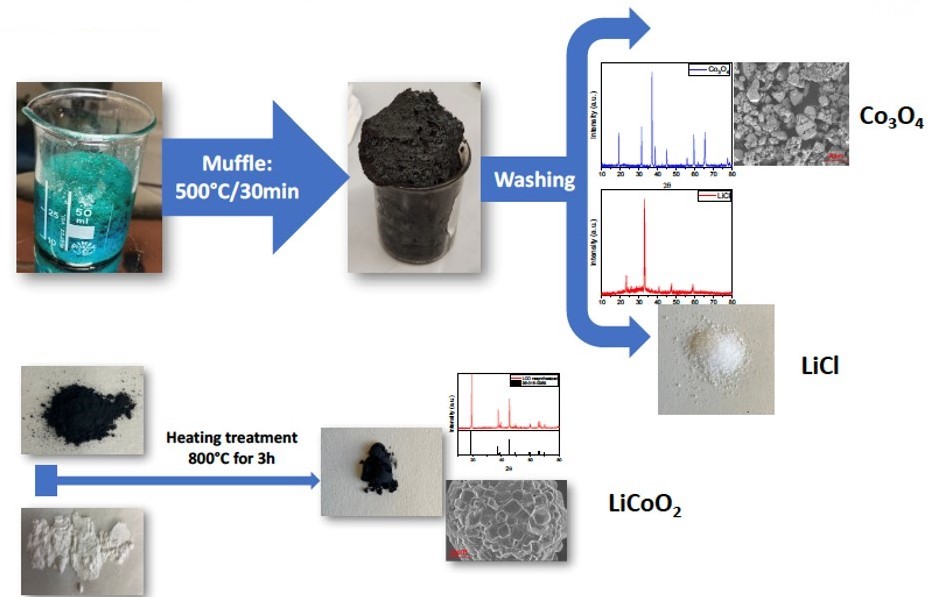

Cathode Recycling by Solvo-Metallurgy:

a) Extraction step via soft-metallurgy (very high extraction rate and soft metallurgical conditions such as low T, shorter t)

b) Synthesis of precursors

c) Synthesis of high-purity CAMs

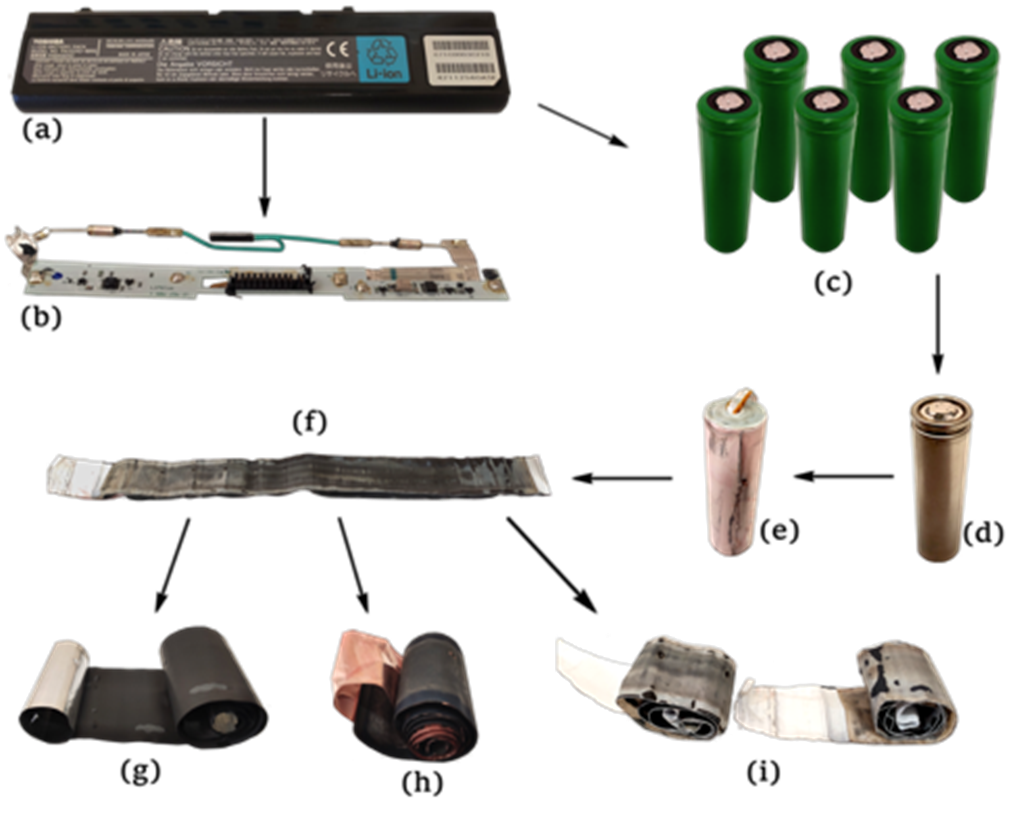

Another primary target of the R2BATT line of research is the methods validation in the reference use-cases:

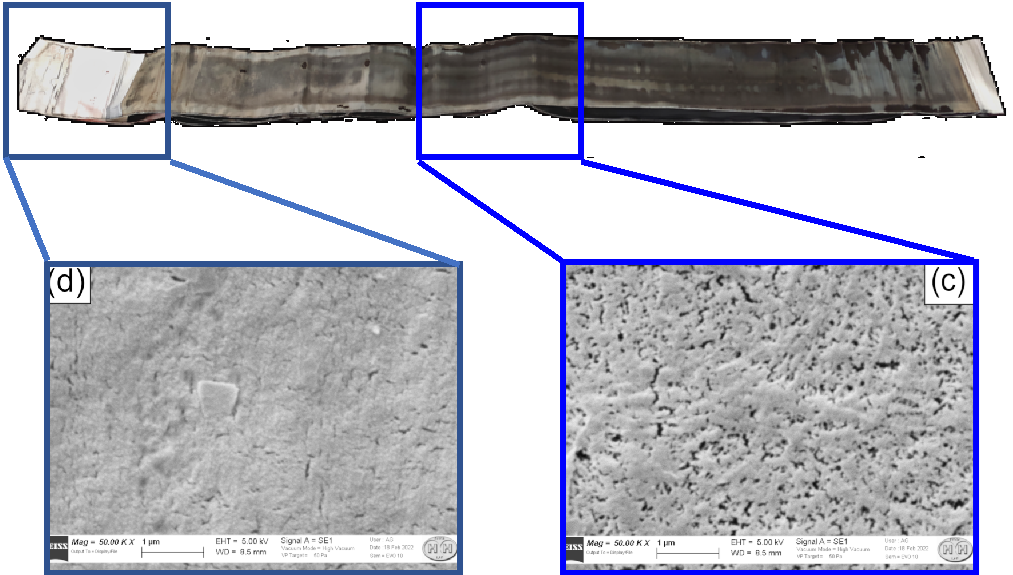

- Battery pack disassembling & component sorting

- Separator recovery

- Cathode recovery:

- PVDF

- Precipitation as PVDF+C

- Purification

- Active Material

- Soft-solvometallurgy via DES (ChCl/LA 1:2) – 1st pathway

- Cathode Healing – 2nd pathway

- PVDF

- Electrolyte recovery

- Anode recovery

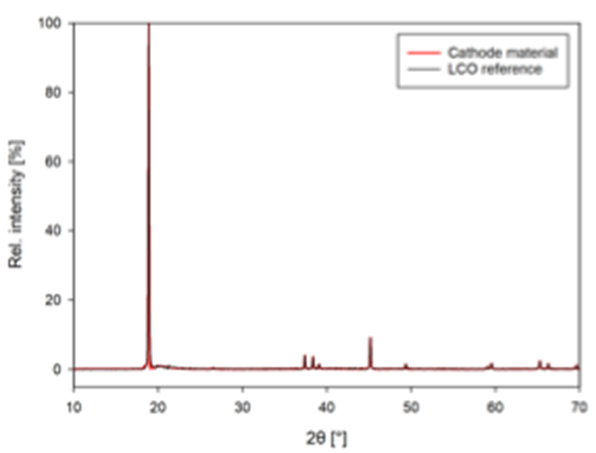

Since the materials characterization is fundamental both before and after the recovery steps of every component, R2BATT can provide and manage different techniques.

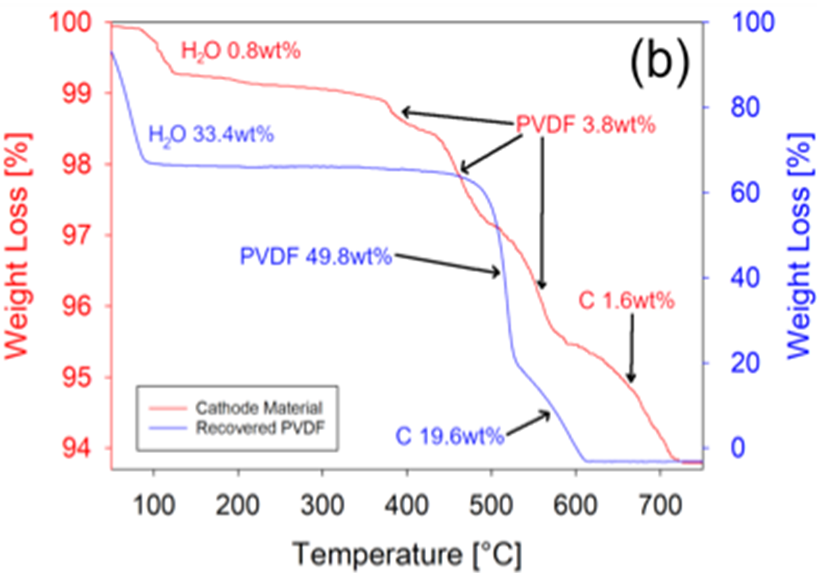

Cathodes components characterization (example):

- XRPD for the active material

- TGA to identify the composition

- ICP-OES to quantify the Li-content

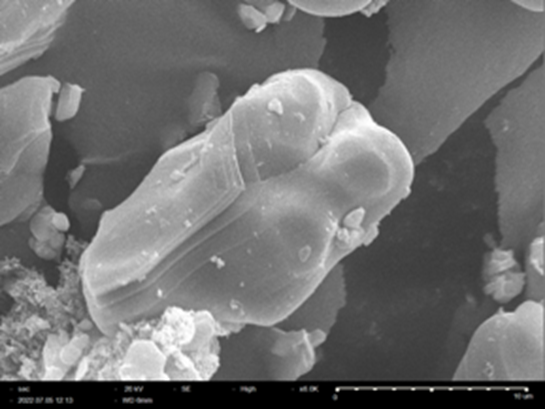

- SEM for the morphology

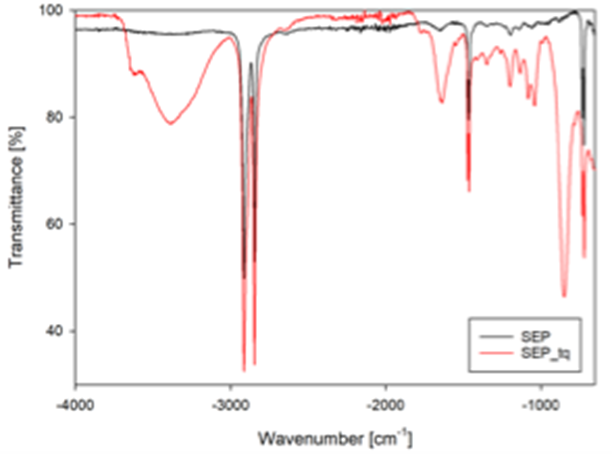

Separators components characterization (example):

- DSC & FTIR to characherize the substrate

- SEM for the morphology

And, last but not least, it is fundamental to measure and evaluate the functional performances of fully recycled components